Innehållsförteckning

Now more than ever before, speed to market and operational efficiency are the determining factors for success in the volatile, fast-paced world of manufacturing. Companies are turning to Lean manufacturing practices to create a sustainable competitive advantage.

5 Lean Manufacturing Principles

Läs vitbok • 5 Lean Manufacturing PrinciplesAgilePlace Free Trial: AgilePlace Online Kanban Software

Sign up for a 30-day free trial and you and your team can start building online Kanban boards today. Experience for yourself how AgilePlace supports continuous delivery initiatives, eliminates waste and improves your team’s delivery processes and speed.

Börja utvärdera kostnadsfritt • AgilePlace Free Trial

Lean manufacturing provides a systematic method for minimizing waste within a manufacturing system, while staying within certain margins of control such as productivity and quality, allowing companies to reach the operational efficiency they need to get ahead of the competition.

Because of its long history in manufacturing, it can be tricky to understand exactly what is included in the modern Lean manufacturing definition. In this article, we’ll define some proven Lean manufacturing techniques, share four examples of Lean manufacturing in practice, and dive deeper into Lean principles to help you gain a better understanding of how Lean manufacturing works in practice.

Lean Manufacturing Techniques

Continuous Improvement (Kaizen)

Kaizen is a Japanese word that means continuous improvement. It comes from the Japanese words “kai” which means “change” or “to correct” and “zen” which means “good.”

Continuous improvement is at the heart of any Lean manufacturing practice.

Kaizen is a mindset, a practice, and an approach to work that encourages every part of the value stream to proactively look for ways to improve work quality and reduce waste.

Error-Proofing (Poka-Yoke)

One of the best ways to reduce waste is to prevent it from happening in the first place. One key Lean manufacturing technique is poka-yoke, a Japanese phrase that translates to “mistake-proofing” or “error-proofing.” This Lean technique encourages the use of visual signals, tools, and systems that make waste due to human error extremely unlikely.

Some examples of error-proofing that you might encounter in your own life might include:

- The attachment on your gas cap in your car keeps it attached to your car.

- Microwaves and washing machines do not turn on unless the door is closed.

- Elevator doors have sensors to make sure nothing is obstructing the door before it closes.

In Lean manufacturing, some examples of error-proofing include:

- Using standardized containers at the workstation enables workers to know exact quantities without having to weigh or count the contents.

- Power guards on machines with moving parts prevent opening until the parts have stopped completely in order to prevent accidents.

- Safety mats near machine areas that pose a danger automatically trigger stoppage when someone steps on them, preventing injury to workers operating the machines.

- In food processing, workers typically wear blue gloves and other protective clothing, so that it is easy to spot in food (blue is not a naturally occurring color in food).

5S

Another Lean manufacturing technique that can be used to reduce waste is known as “5S.” Similar to the cooking concept of “mise en place” (a French phrase meaning “everything in its place”), using the 5S helps to eliminate waste by keeping workstations organized and prepared for the tasks at hand.

5S includes:

- Sort: Remove any unnecessary tools from the workspace

- Set-in-Order: Organize the tools that are required for the task at hand so that they are easy to find

- Shine: Keep the workplace clean and tidy

- Standardize: Establish guidelines or requirements that all items must meet

- Sustain: Minimize waste by maintaining the standards of each workspace as determined by the other 4S

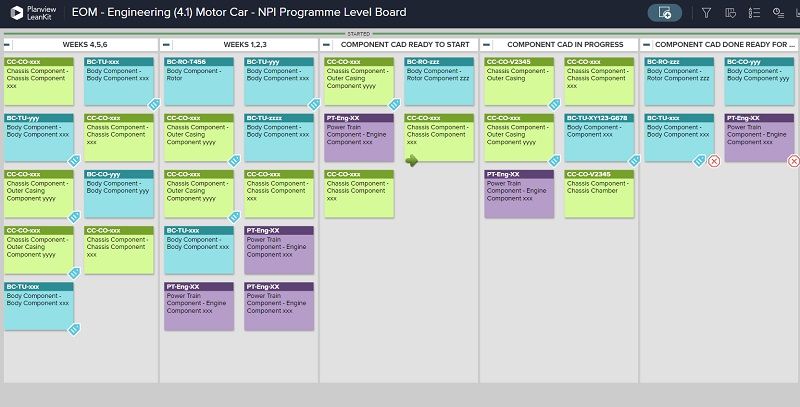

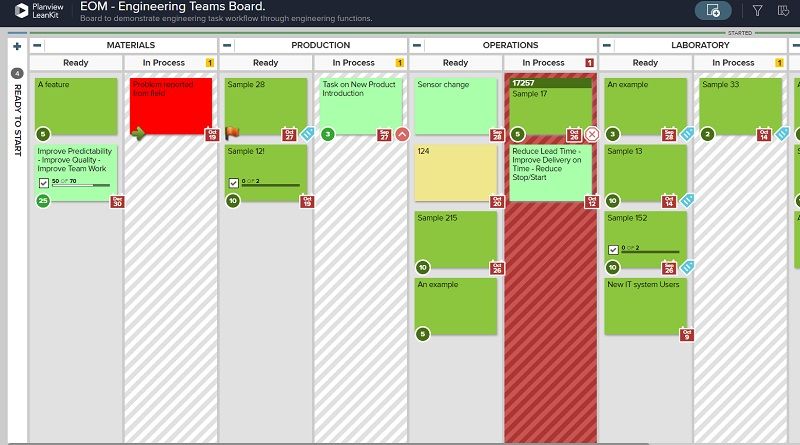

Kanban Visual Management

Kanban is a workflow management tool that is used in Lean manufacturing to visualize and manage all work in process. Kanban helps to reinforce some of the key elements of Lean, including:

- Limiting work in process (WIP)

- Using a pull system (as opposed to a push system)

- Managing capacity to improve flow

- Visualizing work

Just-in-Time

Just-in-Time manufacturing is another Lean manufacturing technique used to minimize waste and maintain profitability of businesses. It’s a production strategy that aims to help manufacturers improve their return on investment (ROI) by reducing in-process inventory and the associated costs.

In a Just-in-Time system, raw materials are purchased and turned into finished products just in time to meet customer demand. This ensures that Lean manufacturers are not overproducing or holding onto excess inventory, two forms of waste.

Stop the Line (Jidoka)

When an error occurs on a production line, two things must happen: The error must be corrected, and the cause of the error must be identified so that it does not continue to occur. Otherwise, the error might be repeated, creating more waste.

The Lean technique known as “stop the line,” is the practice of pausing production to perform root-cause analysis in the moment that errors occur.

Stopping the line is an effective way to not only correct errors, but help the team prevent future errors by involving everyone on the line in the problem-solving process. It encourages teams to work together to quickly define problems and come up with effective, permanent solutions.

Takt Time

Takt time is the measure of how long it takes a system to meet the demands of the customer. More specifically, it’s the average time between the start of production of one unit and the start of production of the next unit, when these production starts are set to match the rate of customer demand.

Takt time = Available Time / Required Output

In Lean manufacturing, takt time is used to balance production to prevent inventory buildup or shortages.

Production Leveling (Heijunka)

Another Lean technique used to reduce waste in production is production leveling or smoothing (heijunka in Japanese). Heijunka helps Lean manufacturers ensure an efficient flow of production while accounting for fluctuations in customer demand.

Rather than manufacturing in batches or to-order based on customer demands, Lean manufacturers use heijunka to reasonably estimate what mix and quantity of products to produce in a period of time.

To do this, they take the total volume of orders over a period of time, and then use this to produce the same volume and mix of products each day.

This provides:

- Predictability, by accounting for fluctuations in demand

- Flexibility, by decreasing changeover time

- Stability by ensuring that production volume and type is balanced

4 Examples of Lean Manufacturing Practices

Lean manufacturing offers a holistic approach to improvement, with the methods, tools, and cultural ideals that companies need to stay innovative and agile. These examples of Lean manufacturing practices enable organizations to become nimbler and more innovative.

Value stream mapping

Value stream mapping can be used to improve any process where there are repeatable steps, especially when there are multiple handoffs. It’s easiest to think of a value stream like an assembly line, but there is obviously a large part of the manufacturing value stream that is not done on an assembly line. Most of the engineering, development, research, and design in manufacturing is done inside the heads of knowledge workers, making it trickier to spot inefficiencies.

Much of the waste in knowledge work occurs in the handoffs (or wait time) between team members, not within the steps themselves. Inefficient handoffs in knowledge work may not look like bottlenecks on a car assembly line, but they produce the same effects:

- Decreased productivity

- Overwhelmed workers

- Lower work quality

Analyzing and aiming to eliminate these inefficiencies at the organizational level is the first step toward becoming leaner.

Lean actions can be focused on specific logistical processes or cover the entire supply chain.

For example, an analysis of a SKU would look like this: First, aim to visualize its path, evaluating all the participants from material suppliers to the consumer, and then conduct a gap analysis to determine necessary next steps to improve the value stream and achieve the objective. Then, make these small improvements over time throughout the supply chain, increasing organizational learning and streamlining the process of creating that SKU.

Demand-based flow (pull) manufacturing

In a pull system, inventory is only pulled through each production center when it is needed to meet a customer’s order. Pull systems in lean manufacturing allow “just-in-time” delivery of work. Unlike other work methods that allow for an unlimited amount of work at once, a pull system enables everyone at a specific organizational level to focus on one thing (or just a few things) at one time.

The benefits of using a pull system include:

- Ability to manage change

- Ability to quickly adapt work to new information

- Increased ability to scale the team to the appropriate size for the project

As they work through a list of “to-do” items in a backlog, team members pull new tasks only as old tasks are completed. This way, when something changes that impacts the business requirements (as it always does), the team can quickly adapt, knowing that most of the work they have already completed can still be applied to the project.

Finally, because teams using a pull system are self-managed to a certain degree, pull systems contribute to the scalability of a team, or the ability for a team to accommodate different-sized projects while remaining cohesive. For manufacturers, this means teams can:

- Be more agile

- Deliver faster

- Innovate faster and more strategically

Organizations who adopt a Lean pull system are also able to significantly improve the reliability and accuracy of forecasting for their suppliers and customers.

Continuous improvement mindset

An organization-wide commitment to continuous improvement (Kaizen) is essential for sustainable success with Lean manufacturing.

At its core, Lean is continuous improvement – it’s improving product and process while eliminating redundant, excessive, or inefficient activities.

Continuous improvement can be viewed as a formal practice or an informal set of guidelines, but it must be well-integrated into the culture of an organization in order to make a meaningful and lasting difference.

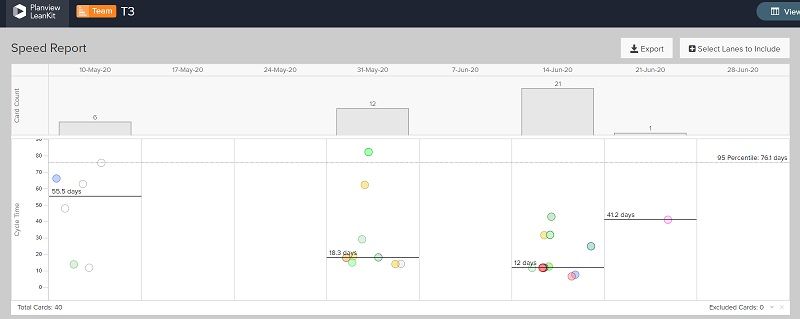

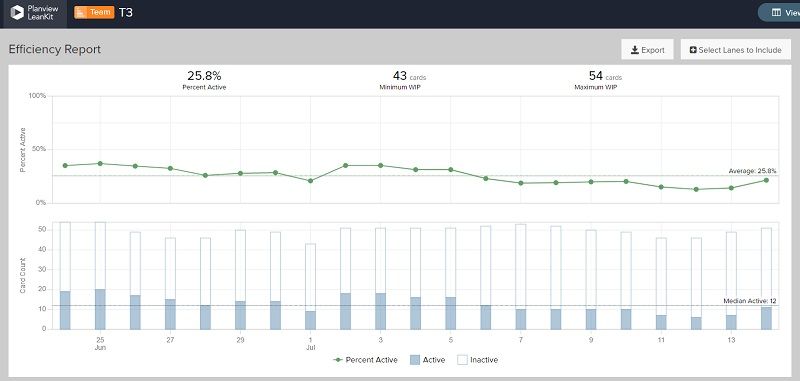

Measurement, KPIs, and visualization

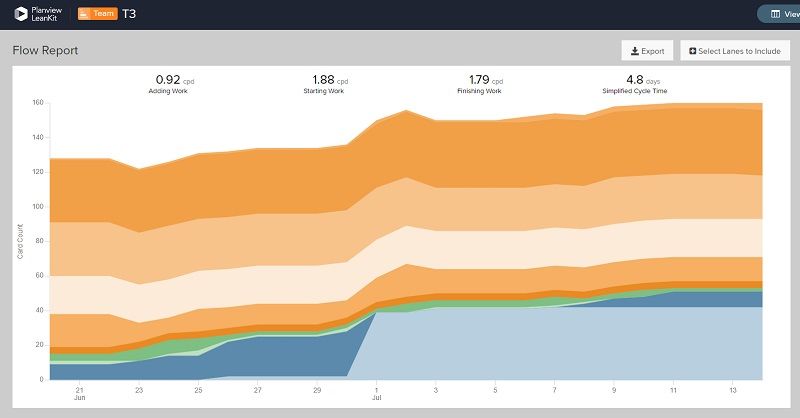

Lean manufacturing metrics, such as lead time, cycle time, throughput, and cumulative flow, help organizations measure the impact of their improvement efforts. Collecting, analyzing, visualizing, and socializing these metrics (through shared dashboards) is essential to promoting transparency and driving change.

Successful Lean manufacturers use up-to-date dashboards at the team, leader, and executive levels to paint an accurate picture of the impact that changed processes are having. It should be noted that the emphasis is on surfacing key performance indicators of processes, not people. This reinforces a collective responsibility by teams to pursue opportunities for improvement and focus on value creation for customers.

7 Lean Manufacturing Principles

There are seven fundamental principles of any Lean practice, which are used in Lean manufacturing, but also in all disciplines of knowledge work. A firm, shared understanding of these Lean manufacturing principles is essential for any organization hoping to sustainability and holistically adopt Lean manufacturing practices.

Optimize the whole

Every business represents a value stream, the sequence of activities required to design, produce, and deliver a product or service to customers. If our goal is to deliver as much value to our customers as quickly as possible, then we have to optimize our value streams to be able to do just that. In Lean manufacturing, this means creating seamless, productive systems on the shop floor, but also optimizing efforts across knowledge workers – engineers, developers, and others.

Eliminate waste

Lean manufacturing defines waste as anything that doesn’t add value to the customer. This can be a process, activity, product, or service – anything that requires an investment of time, money, and talent that does not create value for the customer is waste.

Industry trends show that companies adopting Lean manufacturing principles develop products by up to six months faster and stay 35% closer to products’ target costs than their competitors.

Eliminating waste across the value stream, instead of at isolated points, helps manufacturers create processes that require less human effort, less space, less capital, and less time to deliver products and services that cost less and have fewer defects.

Build quality in

As businesses grow, the limitations of homegrown systems expose themselves. Lean manufacturers set themselves up for sustainable growth by practicing the Lean principle of Building Quality In.

The concept is simple: Automate and standardize any tedious, repeatable process, or any process that is prone to human error. This allows Lean manufacturers to error-proof significant portions of their value streams, so they can reduce risk and time to market and focus their energy on creating value for their customers.

Some examples of this Lean manufacturing principle include:

- Pair programming: Avoiding quality issues by combining the skills and experience of two developers instead of one

- Test-driven development: Writing criteria for a product/feature/part before creating it to ensure it meets business requirements

- Incremental development and constant feedback

- Minimize wait states: Reducing context switching, knowledge gaps, and lack of focus

Deliver fast

When a piece of work reaches the customer, it’s valuable. Until then, it isn’t.

The Lean principle of Deliver Fast by Managing Flow is based on the idea that the faster we can deliver bits of value to our customers, the sooner we can begin to learn from customer feedback. The more we learn from our customers, the better able we are to give them exactly what they want.

To deliver fast, we must manage flow, by limiting work in process and maintaining a relentless focus on value delivery. In Lean manufacturing, specifically, there is a heightened need to deliver quickly, because the cost of delay can run upwards of millions of dollars per day. Reducing development cycles and delivering new products or features quickly is essential for sustainability in manufacturing.

Create knowledge

The Lean principle of Create Knowledge is related to the concept of Optimizing the Whole.

A Lean organization is a learning organization; it grows and develops through analyzing the results of small, incremental experiments.

In order to retain that information as an organization, the learning must be shared. The Lean principle of Create Knowledge says that Lean organizations must provide the infrastructure to properly document and retain valuable learning, so they do not repeat mistakes.

Defer commitment

Lean thinking is derived from the manufacturing philosophy of Toyota, which emphasized a just-in-time system of inventory management. The Lean principle of Defer Commitment says that Lean organizations should also function as just-in-time systems, waiting until the last responsible moment to make decisions. This allows Lean manufacturers to have the agility to make informed decisions, with the most relevant, up-to-date information available.

Respect people

The success of any Lean initiative hinges upon one Lean principle: Respect People.

- Out of respect for the customer, we make decisions that will bring them the most value with minimal waste.

- Out of respect for our employees, we create environments that allow everyone to do their best work.

- Out of respect for our coworkers, we continuously strive to optimize our processes to allow everyone to deliver the most value they can provide.

Especially in manufacturing organizations, which often have teams working across the globe with different cultures, languages, and backgrounds, putting respect at the forefront of every interaction is critical for creating the type of safe, innovative workplace that will attract and retain top talent.

Lean Manufacturing in Practice

In the world of manufacturing, operational efficiency is everything. The techniques, tools, and principles of Lean manufacturing offer a systematic method for minimizing waste within a manufacturing system, allowing companies to reach the operational efficiency they need to get ahead of the competition.