Table of contents

Although manufacturing today looks quite different from the shop floors of the early to mid-twentieth century, many of the basic principles still hold true. These modern Lean manufacturing principles are helping organizations drastically reduce time to market, increase innovation, and add more value for their customers in a fast-paced and ever-changing global marketplace.

5 Lean Manufacturing Principles

Read the whitepaper • 5 Lean Manufacturing PrinciplesPlanview AgilePlace: Optimize your business flow to deliver more value

Watch the demo to see how AgilePlace can help you see the big picture, drive agility, integrate applications, and improve continuously.

Watch the product demo • Planview AgilePlace

Why Lean Manufacturing?

In order to remain competitive, manufacturing organizations have to be in a constant mode of continuous improvement, finding ways to improve time to market (TTM) and increase innovation, while lowering costs, streamlining processes, and adapting new technologies. Lean manufacturing provides a holistic approach to systematically eliminating waste from processes and systems so organizations can sustainably deliver quality products more quickly to their customers.

The Principles of Lean Manufacturing

The following Lean manufacturing principles can be applied to virtually any industry and team type.

Optimize the Whole

There’s a famous quote from Aristotle that applies well to Lean manufacturing: “The whole is greater than the sum of its parts.” Lean manufacturing is rooted in systems thinking–the practice of studying the system and each of its individual parts, in order to make decisions that enable the organization to do its best work.

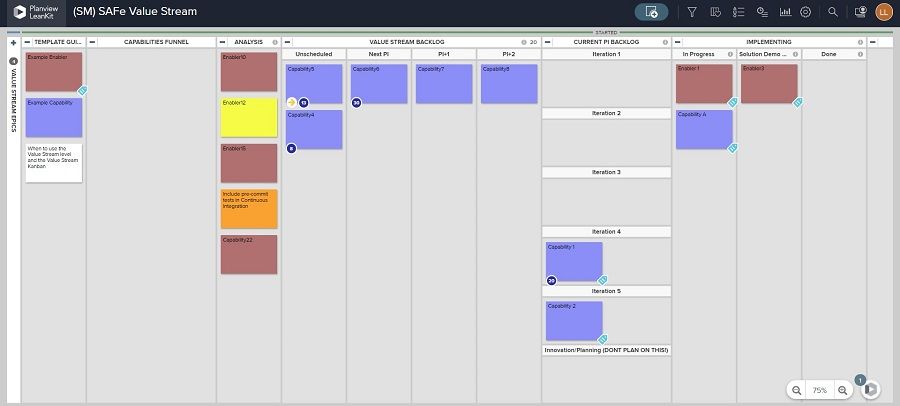

This is why value stream mapping is such an important part of any Lean implementation: In order to optimize the whole system for the delivery of value, it’s essential for teams to have a clear understanding of how all of the pieces work together.

Otherwise, the value stream mapping exercise risks optimizing one part of the system at the cost of sub-optimizing another.

Optimizing the whole means:

- Defining and visualizing the value stream and all of its respective parts

- Forming cross-functional teams that work towards shared goals and objectives

- Conducting strategic planning across the entire organization

- Amplifying the voices of frontline workers / the people closest to the work

- Making decisions with respect to the entire value stream

Eliminate Waste

In Lean thinking, waste refers to any activity, product, or service that does not add value to the customer. In Lean manufacturing, most of the waste comes from inefficiency; it’s the excessive time, energy, labor, and money spent developing products that don’t meet market demands. The Toyota Production System outlines eight types of waste, which can be a helpful model for identifying waste in an organization that is practicing Lean manufacturing principles:

| Waste of overproduction | Producing more than is necessary |

|---|---|

| Waste of time on hand | Delays or idle time (often in handoffs between steps in the process) |

| Waste of transportation | Moving goods or materials from one place to another unnecessarily |

| Waste of processing | Happens when a poor process or tool results in more processing than is necessary |

| Waste of excess inventory | Purchasing materials or manufacturing products ahead of demand |

| Waste of movement | Unnecessary motion of materials, people, or products |

| Waste of making defective products | The effort involved in inspecting for and fixing defects; can be avoided by building quality into the system |

| Waste of underutilized workers | Not balancing capacity effectively; underutilizing some team members or teams while overburdening others |

All of this process waste results in a more expensive and lower quality product for the customer.

Eliminating waste across the value stream, instead of at isolated points, helps manufacturers create processes that require less human effort, less space, less capital, and less time to deliver products and services that cost less and have fewer defects.

In fact, industry trends show that companies adopting Lean manufacturing principles are developing products by up to six months faster and staying 35% closer to products’ target costs than their competitors.

Deliver Fast by Managing Flow

Manufacturers have notoriously long design and production cycles, which equate to huge cost of delay and a crippling lack of agility. Some of this is due to the complexity of products or the liability involved, especially for auto or aerospace manufacturers. Some of it is due to a lack of organizational focus; many manufacturers produce hundreds of products, making it difficult to analyze performance or leverage feedback from customers to make meaningful improvements.

A key element of Lean manufacturing is that in order to deliver value quickly, companies must focus on managing the flow of ideas, products, services, and improvement efforts across their value streams.

In an industry where cost of delay can be measured in millions of dollars per day, improving flow with Lean manufacturing principles can make a significant impact on the bottom line.

A tangible and effective way to deliver faster is to implement WIP, or work-in-process, limits. WIP limits are fixed constraints that enable teams to stay focused on their top priorities. Instead of spreading their attention, energy, and time across hundreds of things at once, WIP limits encourage teams to focus on a handful of products at once and deliver them as quickly as possible.

This means that employees can dive deeper and add more value to the tasks at hand, which can improve job satisfaction and boost employee retention rates. This is especially important in an industry with a seasoned workforce and steep competition from the tech industry for top talent.

Practice Iterative Development

Iterative development is a hallmark of Lean software development and one of the key Lean manufacturing principles. Lean development is based on this concept: Build a simple solution, put it in front of customers, and enhance it incrementally based on customer feedback.

Testing concepts before making greater investments in raw materials and equipment can save manufacturers millions of dollars and allow them to provide more value to customers, who no longer have to incur the cost of a lengthy and costly development cycle.

Historically, iterative development has been difficult for manufacturers to do at scale, but Industry 4.0 trends like the Internet of Things, additive manufacturing, digital twins, and digital factories are enabling companies to iterate at a lower cost and higher frequency.

Build Quality In

Building quality and reliability into the design and manufacturing process is the accepted norm (or at least, goal) for manufacturers that are applying Lean manufacturing principles. For many companies, quality equals safety, which means things have to work correctly the first time. Generally, the approach to ensuring quality is to test defects out – to run rigorous tests to ensure that quality meets a certain predefined standard.

Lean thinking reverse-engineers this by encouraging organizations to build quality into the manufacturing process, providing unlimited opportunities to learn and add value to the customer.

In recent decades, many Lean development teams have found success by applying the following Lean development tools to build quality into their work. In Lean development, quality is everyone’s job, not just QA’s.

Here are a few practical examples of the principle of building quality in:

- Pair programming: Avoiding quality issues by combining the skills and experience of two developers instead of one

- Test-driven development: Writing criteria for a product / feature / part before creating it to ensure it meets business requirements

- Incremental development and constant feedback

- Minimize wait states: Reducing context switching, knowledge gaps, and lack of focus

- Automation: Automate any tedious, manual process or any process prone to human error

Defer Commitment

Lean manufacturing principles apply as much to planning as they do to work that’s in process. In fact, in a world where market realities can shift literally overnight, one of the greatest sources of waste is planning. This is not to say that Lean organizations do not plan–but they do avoid spending time creating extensive, detailed plans that might never happen.

The Lean principle of Defer Commitment says that Lean organizations should function as just-in-time systems, waiting until the last responsible moment to make irreversible decisions. To use an analogy, instead of writing books of plans for years ahead, Lean organizations draft up outlines, and fill in the bullets as they go. Doing this allows Lean manufacturers to maintain the agility to make informed decisions, with the most relevant, up-to-date information available.

Create Knowledge

A Lean organization is a learning organization; it grows and develops by analyzing the results of small, incremental experiments. One of the Lean manufacturing principles that emphasizes learning over perfection is the action of “creating knowledge,” which encourages transparency and thoughtful experimentation.

When things go wrong, the question is not, “Whose fault is this?”, but, “What did we learn from this, and how can we prevent it in the future?”

In order to retain that information as an organization, the learning must be shared. The Lean principle of Create Knowledge says that Lean organizations have to provide the infrastructure to properly document and retain valuable learning, so they do not repeat mistakes.

Respect for People

A seasoned workforce and competition for top talent from tech companies are forcing manufacturers to change their talent management philosophies to nurture a culture of innovation.

Top engineering candidates are seeking work experience that is as stimulating, engaging, challenging, and enriching as the tech-enabled world they live in. These candidates know they can get a high salary, good benefits, and startup-y perks anywhere – what they really crave is to do meaningful work in a forward-thinking organization that is making a difference in the world.

Embracing the Lean concept of respect for people, as many tech companies have, could be key to fulfilling this lofty vision. In this case, respect for people means that organizations do everything they can to create value for both prospective and existing employees. This means finding ways to attract and retain new talent by adding value to their experience. It also means supporting existing employees through cultural adjustment.

Of all the Lean manufacturing principles, respect for people might be most challenging to sustainably implement because of the cultural shift it requires.

For engineers who have spent their careers in traditional manufacturing cultures, embracing a culture of innovation may require a new set of social skills, including open collaboration, a free-flowing exchange of ideas, and an overall increase in empathy and flexibility. Practicing respect for people will mean creating an environment where employees of all generations and backgrounds can find room to learn, adapt, and grow in their careers.

Benefits of Lean Manufacturing Principles

From higher quality products to a stronger, more resilient company culture, the benefits of applying Lean manufacturing principles cover a wide range of qualitative and quantitative outcomes. This is possible when manufacturers enact a structured approach to continuous improvement that enables them to eliminate waste and optimize processes. Those core gains often result in companies that are able to cut costs, boost innovation, reduce time to market, and improve quality.

The benefits of Lean manufacturing go beyond the bottom line.

Implementing Lean manufacturing principles can make an organization more efficient and productive — and they can also have deeper cultural benefits that make it worth the investment of time, money, and energy:

- Lean, innovative companies attract and retain top talent.

- A culture of hiring from within encourages employees to invest in themselves in ways that also benefit the organization.

- Lean tools like Kanban make it possible to build and scale global teams.

- Practicing continuous improvement empowers employees to innovate, experiment, and think outside the box.

- Long-lived teams reach higher levels of performance and satisfaction than short-lived teams.

Lean Manufacturing Principles Today

When Lean manufacturing began in the 1950s, it was designed to optimize the logistics, production lines, and use of raw materials in manufacturing value streams. Lean manufacturing principles were focused on eliminating waste, cutting costs, and improving overall efficiency on the shop floor.

Modern manufacturing value streams are looking more like software development value streams – because increasingly, they are. Manufacturers are hiring more and more software engineers as their product lines evolve to incorporate more software.

Today, Lean manufacturing refers more to the optimization of knowledge workers, using Lean principles to work smarter, innovate faster, and deliver more value to customers. By providing a structure to keep teams focused on efficiency and flow, these Lean manufacturing principles are not only making teams more productive, they’re also making manufacturing companies more attractive places to work for talented engineers.